More progress, although mainly fiddly, small tasks. I started the day by removing the old studs from the exhaust manifold. They came out smoothly and were in good condition. The new turbo came with new studs and nuts so they will be kept for spares.

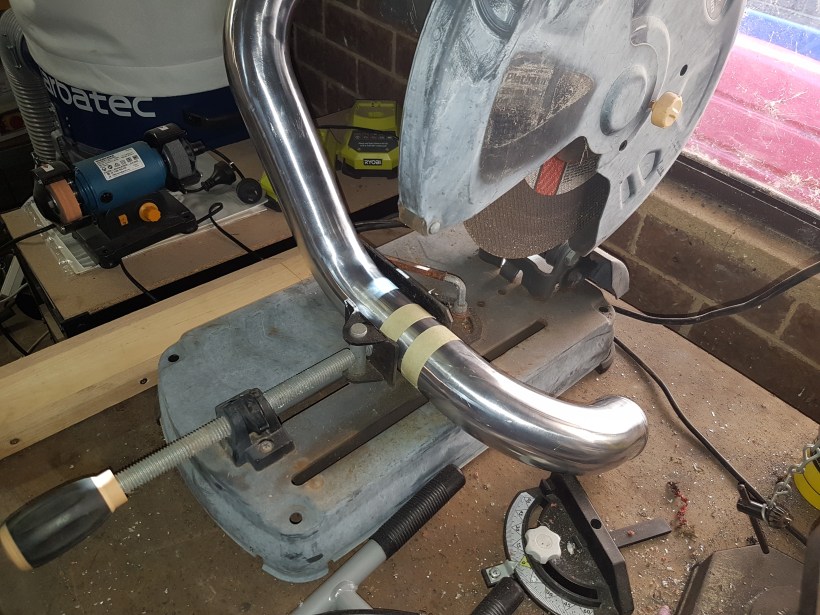

The new studs are quite long and have a square section on top which I used small vice grips to tighten. I used loctite, even though I’m not sure it won’t just burn away but it was worth trying. The picture below shows the long studs fouling in various places so I cut and filed them shorter.

I came across the first problem in the process so far, in that the actuator fouls the intake snorkel.

Fortunately I’m using an external wastegate so the actuator can be ditched. The kit came with an extender for the inlet snorkel but the supplied studs aren’t long enough to fit. Using this with longer bolts (supplied from elsewhere) would be a simple work around for those using the internal wastegate.

Next up I tested fitted the braided water lines and dummy fitted the whole assembly in place. Everything looks like it will sit perfectly so very happy with the job so far.

Finally, I disassembled the actuator and replaced it with a modified bolt. This was tricky because the thread on each end of the original actuator rod is a different pitch. I cut the top off a 1/4 inch bolt (pictured), cut the M6 x 0.75mm thread in its place and then bolted up. The result is a secure, mechanical locking of the internal wastegate flap shut. It is also completely reversible.

Progress now will be stalled until the mild steel flanges arrive in the mail so I can re-plumb the wastegate pipe with the new connection. Very happy so far with how things are going.